- Backup Foot Unloader 2

- Bird Counter

- Burn Eliminator

- Cascading Waterfall-10 ft

- Cascading Waterfall-10 ft-H20

- Cascading waterfall-12 ft

- Cascading Waterfall-7 ft

- Cuticle Brush

- Emech Mixing Valve - Steam

- Emech Mixing Valve - Water

- Finger Master 5000

- Foot Pad Scrubber 3-24

- Foot Pad Scrubber 3-48

- Foot Pad Scrubber-HDE

- Foot Pad Scrubber-HDH

- Foot Picker Direct Drive

- Foot Picker Direct Drive 5-10ft

- Foot Picker Water Recirculation

- Head Puller

- Hock Picker

- In-Line Dip Tank Scalder In-Line Dip Tank Scalder, Dual Lane

- Paw Harvester

- Paw Harvester / FPS Combo / HDE

- Paw Harvester / FPS Combo / HDH

- Paw Harvester Extended

- Paw Harvester-HDE

- Paw Harvester-HDH

- Paw Inspection Table

- Paw Recovery System

- Paw Tracking Conveyor System

- Paw Untangler

- Turbo Rinser

- Whole Foot Harvester

- Wing Picker 2

- Wing Picker 3

- Wing Picker 4

- Wing Scrubber

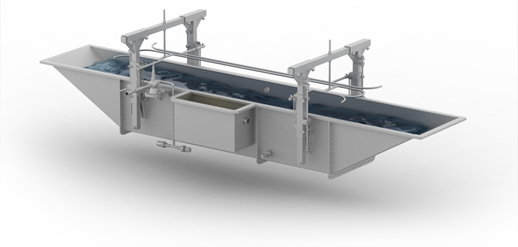

Model # B-DTS-DL-9

The Model B-DTS-DL-9 Berry Dip Tank Scalder with Dual Lane capacity is being used in Paw Harvesting operations on the return line. While remaining on the shackles, the paws are immersed into the tank as the steam injected hot water softens the paws which aids in the removal of cuticle and ammonia burns. This pre-heating method may also be used on Wings to soften cuticle and feathers for easier removal.From the on-line Dip Tank Scalder, the paws may then be fed into the Berry Foot Pad Scrubber.The Foot Pad Scrubber, along with the Ammonia Paw Scraper are designed to improve the appearance of the paws of all size birds lots.

Construction:

The Berry DTS-DL-9 is designed for maximum safety and ease of operation. The machine is constructed entirely of stainless steel and brass for durability and easy cleanup.

Operation:

Paws are lowered into the Berry Dip Tank Scalder where water and steam mix to create the desired temperature for softening the paws for removal of cuticle and ammonia burns. Consistent temperature is maintained through temperature controls. This model has dual lane capacity. Also processes wings to soften feathers for easier removal.

Maintenance:

With proper operation, the only maintenance the Berry Dip Tank Scalder requires is daily cleaning and checking of various parts for wear and tear, or possible leaks.

Optional:

1-1/2" Steam Emech mixing valves can be used as an addition to the Berry Dip Tank Scalder to guarantee precise temperatures.